[LG ELECTRONIC]

Each year, millions of home appliances reach the end of their operational lifespans and are taken away for disposal.* However, their story doesn’t have to finish there. Through transformative processes and technologies, these discarded devices can be reborn as brand-new appliances, offering features and performance tailored to the needs and preferences of today’s consumers.

Let’s explore how old appliances are being turned into up-to-date and environmentally-conscious living solutions by one of the leading innovators in the home appliance industry.

Recycled plastics: Giving life to LG’s captivating designs

Recycled plastics play an important role in bringing the captivating designs of LG’s home appliances to life, including those of the recently launched LG Styler ShoeCare and ShoeCase. The LG PuriCare AeroFurniture air purifier and the LG tiiun mini, which come in an array of vibrant colors to enliven the home, also employ recycled plastics. Used in the construction of both products’ exteriors, these repurposed materials contribute to the aesthetic appeal of LG’s innovations and help reduce resource consumption and waste.

A continuous virtuous cycle for the planet and consumers

LG has fully embraced a ‘Sustainable Cycle’ approach, building eco-consciousness into every stage of the home appliance lifecycle, from production and packaging to usage and recycling. The company continues to utilise recycled materials extracted and processed at the CRC in the manufacture of new appliances – appliances that minimise power consumption and emissions, and are themselves highly recyclable. In this way, LG has created a virtuous cycle that simultaneously benefits the planet and consumers.

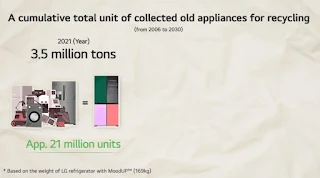

Stepping up its efforts even further, LG plans to reach a cumulative total of 600,000 tons of recycled plastics (for producing home appliance components) by the beginning of the next decade. The ambitious target is set out in the company’s ‘Better Life Plan 2030,’ and also forms part of LG’s broader strategy to achieve carbon neutrality.

Also by 2030, LG estimates it will have recovered 8 million tons of out-of-use appliances for the purpose of extracting recycled materials.

By implementing initiatives such as proper product disposal and the extraction of materials from discarded products, LG is able to create something new from something old, showing how a firm commitment to people and the planet can help make a better life for all.

Urban Mining: Unearthing new resources from discarded appliances

‘Urban mining’ means extracting valuable resources from ‘retired’ household appliances. It involves recovering and sorting any raw materials that can be used in the creation of new products. Unlike incineration – a fate that befalls many disused appliances – this course of action helps reduce carbon emissions and prevent environmental pollution. An active urban miner, LG extracts several different materials from discarded appliances – including plastic, iron, and non-ferrous metals – and then uses them to help produce its advanced, new offerings.

LG Recycling Center: Giving new life to old appliances

Since the end of 2021, LG has been implementing resource circulation programs in a total of 52 countries worldwide as part of its extensive efforts to combat greenhouse gas emissions. At the LG Recycling Center in South Korea, which commenced operations in 2001, raw materials are harvested from disposed-of home appliances, meticulously sorted and processed before being made into ‘fresh’ eco-responsible appliance components.

Here are the four main steps taken at the LG Recycling Center that make it possible to turn old appliances into high-quality parts for new products.

Step 1: Collection – Used appliances such as refrigerators, washers and air conditioners are collected and transported to the center.

Step 2: Disassemble and Crush – The appliances are taken apart, and the components are crushed to achieve a consistent size.

Step 3: Sorting and Processing – After iron, aluminum, copper and plastic materials have been sorted, the plastics are put through an additional process where they are made into pellets; a convenient and renewable resource for the manufacturing of plastic parts and goods.

Step 4: Rebirth – The pellets are melted and transformed into plastic parts for use in the production of new LG home appliances.

0 Ulasan